The characteristics, classification and principle of PVC extrusion profiles

PVC extruded profiles are industrially produced PVC products that are produced through continuous high-temperature extrusion of PVC epoxy resin and various additives. According to the characteristics, it can be divided into two types: hard and soft.

In the construction of construction projects, PVC profiles with bending stiffness are used, such as PVC grooves, PVC doors and windows, PVC wooden floors, PVC pipes, etc.

The PVC profile with additives has anti-aging, UV shielding, corrosion resistance, high tensile strength, cheap price, good thermal insulation and fire resistance, and can partly replace aluminum profiles, stainless steel plates, etc., and the air pollution is lower than that of aluminum profiles.

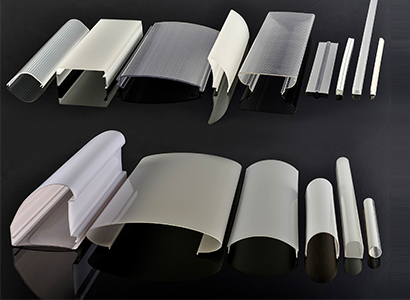

PVC extruded profiles belong to a kind of cross-sectional non-annular extruded rubber and plastic products, which can be called plastic-based profiles. In addition to round, square, and plate PVC aluminum profiles, there are also corrugated paper, Grooves and T-shaped ones are widely used in manufacturing industries such as decoration and furniture. Profiles are mostly made of PVC epoxy resin glue as the raw material, and then add different additives and coordinating agents, and then produce English cross-sections according to the extrusion process. An extruded profile product.

Extrusion forming: alias pvc wire forming, mainly suitable for the forming of thermosetting plastics, and also suitable for the forming of some thermosetting plastics and elastomer materials with very good fluidity. The whole process of forming is to use the rotating extruder extruder screw to extrude the heated and melted thermosetting plastic raw material from the automobile engine with the required cross-sectional shape, then shape it by the shaper, and then cool it according to the glass fiber reinforced plastic cooling tower. Hard and dry, it becomes a product that requires a cross section.

Manufacturing process characteristics:

1. Low cost of mechanical equipment;

2. The operation process is simple, the whole process of the production process is easy to control, and it is beneficial to continuous automatic production;

3. High production and processing efficiency; uniform product quality and high density;

4. Various cross-sectional shapes can be formed or processed by changing the engine die opening.

PVC挤出型材的特征和分类以及原理

pvc挤出型材是通过pvc环氧环氧树脂和各种各样助剂通过持续高温挤出后建立的工业化生产pvc商品。按特性可分为硬质的的和软质2种。

建筑工程施工中采用弯

曲刚度pvc异型材,如pvc槽、pvc门窗、pvc木地板、pvc管等。

加上了助剂的PVC型材具有抗老化,遮挡紫外线,耐腐蚀,抗拉强度高,价格便宜,保温隔热及耐火性能好,可以一部分替代铝型材,不锈钢板等,空气污染低于铝型材。

PVC挤出异材所属因此一种由横截面式非环状的挤出橡塑制品,可以称作以塑料为重要的异型材,除了圆和方、板的PVC铝型材外,也拥有瓦楞纸、槽和T形这种,十分广泛的应用在装饰装修和家俱等加工制造业。异型材是绝大部分要用PVC环氧树脂胶来作为原材料,接着加上不一样的助剂以及互相配合的用剂,接着再依据挤出加工工艺生产制造成的英语的截面的模样相对复杂的一种挤出异型材的产品。

挤出成形:别名pvc电线成形,重要适合热固性塑料的成形,也适合一部分流动性非常好的热固性塑料和弹性体材料的成形。其成形整个过程是应用旋转的挤出机挤出机螺杆,将被升温熔融的热固性塑料原料,从具有需要截面模样的汽车发动机挤出,接着由定型器定形,再依据玻璃钢冷却塔使之冷硬干固,变为需要截面的产品。

制作工艺特性:

1、机械设备成本低;

2、操作过程简单、制作工艺整个过程很容易控制、有益于进行不断自动化生产;

3、生产加工效率高;产品质量均匀、密度高的;

4、依据变更汽车发动机模口可成形各式各样横剖面模样的产品或生产加工。

Related Products

Submitted successfully

We will contact you as soon as possible