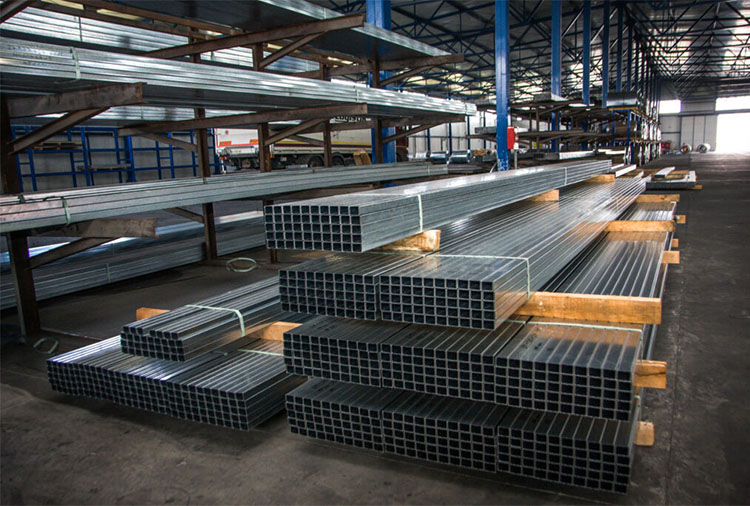

Galvanised Steel Reinforcements for PVC Windows Profiles

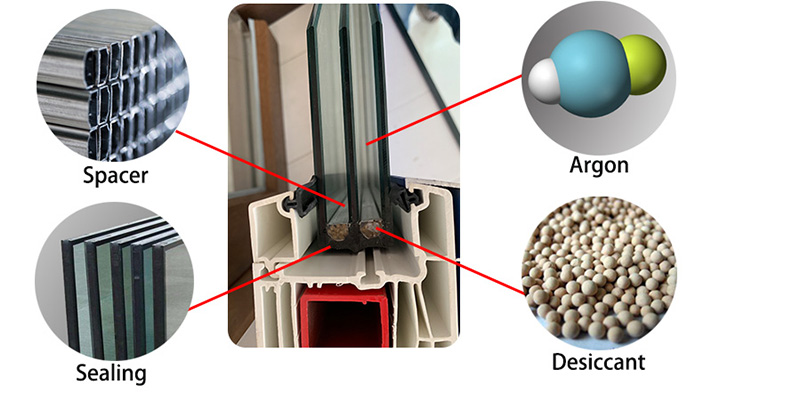

Lume steel reinforcement is of open type, it shall be rolled with material not lower than the mechanical properties of Q235 steel strip specified in GB/T11253, and the inner and outer surfaces shall be cold-galvanized or directly used. When the steel reinforcement is closed, the Q235 steel strip material shall not be lower than that specified in GB/T11253, and the inner and outer surfaces shall be hot-dip galvanized.

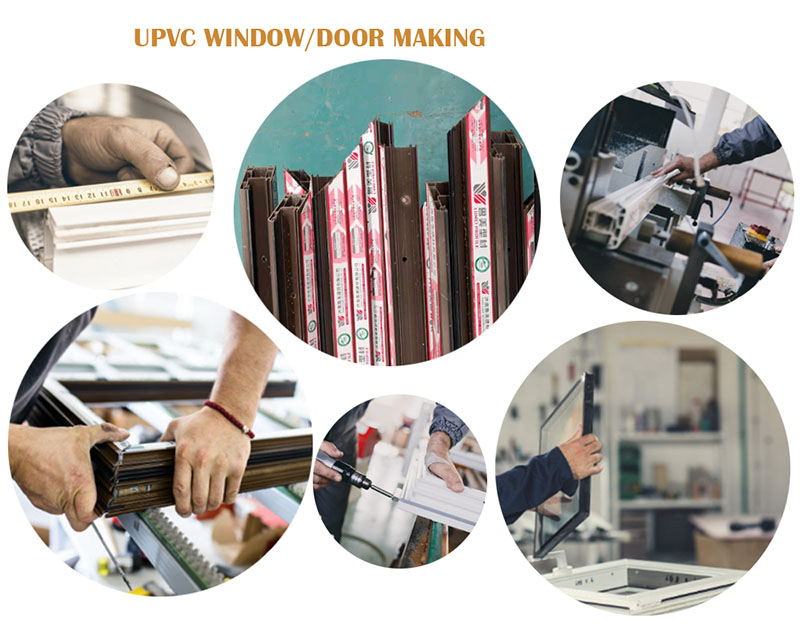

The mechanical homes of inflexible PVC plastics are a long way worse than these of steel, aluminum, and wood. To clear up that problem, metal reinforcement need to be installed. It is very to add metal bolstered metal or metal reinforcement in the cavity of PVC profiles when a single profile of the door and window. The metal reinforcement is of open type, it shall be rolled with fabric no longer decrease than the mechanical homes of Q235 metal strip precise in GB/T11253, and the internal and outer surfaces shall be cold-galvanized or at once used. When the metal reinforcement is closed, the Q235 metal strip fabric shall no longer be decrease than that unique in GB/T11253, and the internal and outer surfaces shall be hot-dip galvanized.

Doors and home windows on the constructing are concern to environmental impacts, normally wind stress and rain and snow, and they should additionally face up to the use of switching forces and their very own gravity. Among them, wind strength is the fundamental purpose for the bending of bars and bars of home windows and doorways (as pass bars, vertical bars and windows), and whether or not doorways and home windows are protected relies upon on their capacity to face up to wind power, commonly on a unit basis.

The mechanical houses of inflexible PVC plastics are a ways worse than these of steel, aluminum, and wood. To resolve that problem, metal reinforcement ought to be installed. it is very to add metal strengthened metal or metal reinforcement in the cavity of PVC profiles when a single profile of the door and window.

1. The window frames, door frames, window sashes, door leaves and their compartment profiles, no count how lengthy every piece of the bar is, as lengthy as they want to be mounted with self-tapping screws and installation hardware fittings on their bars, metal reinforcement have to be installed. Tap the screw on the wall of the metal reinforcement. Without metal reinforcement, the self-tapping screws can solely repair the hardware fittings on the single wall of the PVC profile, and it will be a little tough and the screws will loosen.

two When the window frame, window sash, door frame, door leaf, and their sub-profiles do now not want to be established with hardware fittings, however the size exceeds a positive value, it is additionally critical to deploy metal reinforcement. This size need to be calculated in accordance to the necessities of the door and window on the building's wind stress resistance. However, the real software is based totally on the specs of the window and door profiles, profile wall thickness, and refer to overseas PVC doorways and home windows mounted in the steel reinforcement situation, blended with sensible ride to make sure. In JG/T3017-94 and JG/T3018-94, precise provisions have been made for the addition of metal reinforcement to PVC plastic doorways and plastic windows. Where metal reinforcement is to be established are:

(1) When the side length of the window frame is ≥ 1300mm (50 series or more) and ≥ 1000mm (50 series or less);

(2) When the side window length is ≥1200mm (50 series or more) and ≥900mm (50 series);

(3) When the side length of the side sash of the sliding window sash is ≥1000mm (window fan thickness ≥45mm) and ≥900mm (window fan thickness ≥25mm);

(4) When the side length of the lower border of the sliding sash is ≥ 700mm and the pulley housing does not directly bear the glass gravity;

(5) When the length of the profile (crossbars, vertical bars, etc.) is ≥900mm.

Technical requirements for Steel reinforcement

1. Steel reinforcement material

The metal reinforcement is of open type, it shall be rolled with fabric no longer decrease than the mechanical residences of Q235 metal strip precise in GB/T11253, and the internal and outer surfaces shall be cold-galvanized or immediately used. When the metal reinforcement is closed, the Q235 metal strip fabric shall now not be decrease than that certain in GB/T11253, and the internal and outer surfaces shall be hot-dip galvanized.

2. Steel reinforcement dimension tolerance

The dimensional deviation of the metal reinforcement shall comply with the provisions of JG/T131-2000.

3. Steel reinforcement floor treatment

The metal reinforcement floor is warm dip galvanized (12 μm) floor treatment. After the metal reinforcement is allowed to be rust-removed or acid-cleaned, two layers of antirust paint are utilized rather of hot-dip galvanizing. The steel reinforcement used for magnificent doorways and home windows must be covered with a layer of anti-rust paint after hot-dip galvanizing and cutting.

4. Steel reinforcement length

After the metal reinforcement is processed and fashioned and floor treated, its authentic size is typically 6m, and it is additionally produced in accordance to the order size requirement of the door and window meeting plant or produced by way of 3m and 4.5m. In metal reinforcement packaging, transportation and storage need to be averted from deformation, rust, bulk and so on.

Editor-PVC Profile-rita

Related Products

Submitted successfully

We will contact you as soon as possible