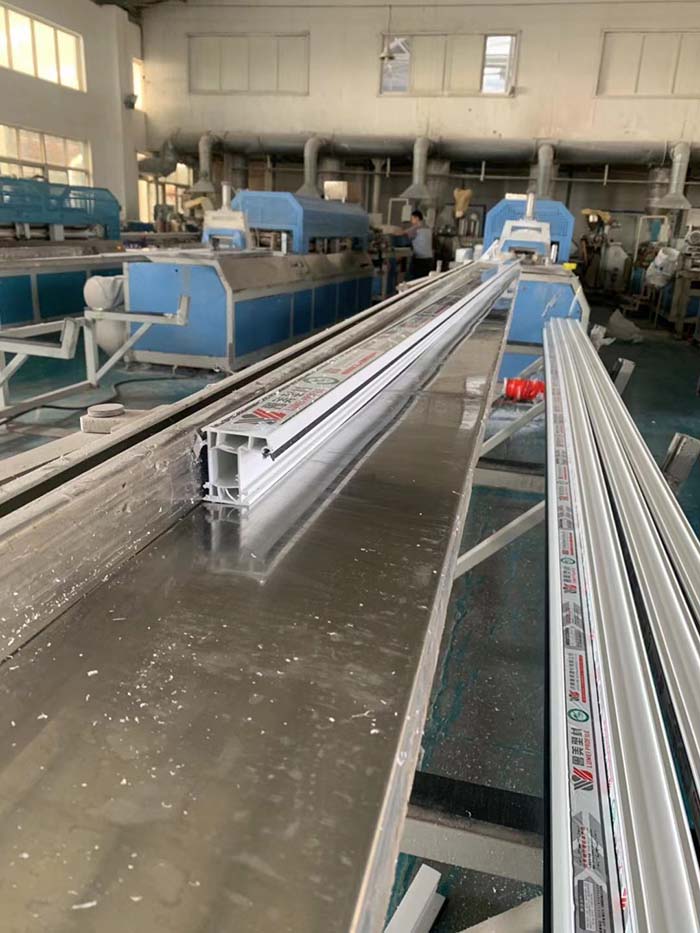

Method of Improving Dimensional Accuracy in the Forming Process of PVC Profiles?

The outlet pressure of the machine is affected by various factors and there are large fluctuations, which will definitely affect the dimensional accuracy of the profile

If we install a melt pump between the outlet of the extruder and the die, it can be used to stabilize the pressure fluctuation at the outlet of the extruder, making linear extrusion possible, thereby improving the dimensional accuracy of plastic products and increasing the output of the extruder per unit time. Melt pump is a kind of positive displacement conveying equipment, high-precision gear clearance and volumetric structure design, which makes stable and balanced extrusion possible. It is widely used in production lines such as chemical fiber, granulation, plastic film, price tag, PVC profile, acrylic lampshade sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion, etc., and has achieved good results:

1. It can realize stable extrusion, improve the dimensional accuracy of extruded products, and reduce the scrap rate. During the extrusion process, it is unavoidable to avoid the phenomenon of uneven feeding amount, fluctuation of barrel and head temperature, and pulsation of screw speed. The use of the melt gear pump can eliminate the feeding error of the feeding system, greatly reduce the fluctuation of the upstream process transmission, quickly enter a stable working state, improve the dimensional accuracy of the extruded product, and reduce the scrap rate.

2. Increase output, reduce energy consumption, realize low-temperature extrusion, and prolong the life of the machine. Since the extruder is equipped with a polymer melt pump, the decompression function of the extruder is transferred to the gear pump to complete, the extruder can work at low pressure and low temperature, the leakage flow is greatly reduced, and the output is increased. Compared with the extruder, the gear pump can effectively build the head pressure, and can reduce the back pressure of the extruder, reduce the axial force on the screw and prolong the service life.

3. With linear extrusion characteristics, it is convenient for upstream and downstream equipment to coordinate work. Since the leakage flow of the gear pump is less, the conveying capacity of the pump is basically in a linear relationship with the rotation speed. After the rotation speed of the gear pump is changed, the flow rate can be accurately known. Since the working speed of the upstream and downstream equipment and the gear pump can be determined synchronously, the online monitoring and feedback control of the entire extrusion process can be realized by using the information such as pressure and temperature collected at the inlet and outlet of the gear pump.

Related Products

Submitted successfully

We will contact you as soon as possible