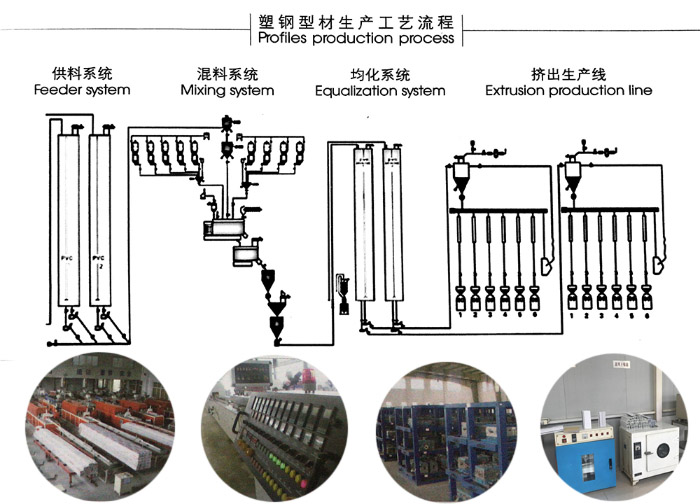

uPVC Profiles Produce Process

Feeder System--The feeder system is an integral component of the extrusion production line for manufacturing PVC profiles for sliding windows and doors. It ensures a consistent supply of raw materials to the mixing system, thereby facilitating a smooth and efficient production process.

Mixing System--The mixing system plays a crucial role in the extrusion production line for PVC profiles. It combines the raw materials, including PVC resin and additives, in precise proportions to create a homogeneous mixture. This ensures the desired quality and performance of the final product.

Equalization System--The equalization system is an essential part of the extrusion production line for PVC profiles. It ensures uniform distribution of the mixture throughout the extruder, resulting in consistent product quality. By maintaining a balanced flow of materials, it minimizes variations in the profiles' dimensions and properties.

Extrusion Production Line--The extrusion production line is a comprehensive manufacturing system used for producing PVC profiles for sliding windows and doors. It encompasses various stages, including the feeder system, mixing system, extruder, and cooling system. This integrated approach ensures efficient and precise production, meeting the stringent requirements of the industry.

Related Products

Submitted successfully

We will contact you as soon as possible