What is the production process of uPVC Profile?

As an energy-saving insulation material, uPVC Profile has inherent advantages. Non-metallic materials have poor heat transfer capacity, which promotes the low heat transfer coefficient of plastic steel profiles. It is very easy to achieve low thermal conductivity when making windows and doors. It is an ideal energy-saving insulation material.

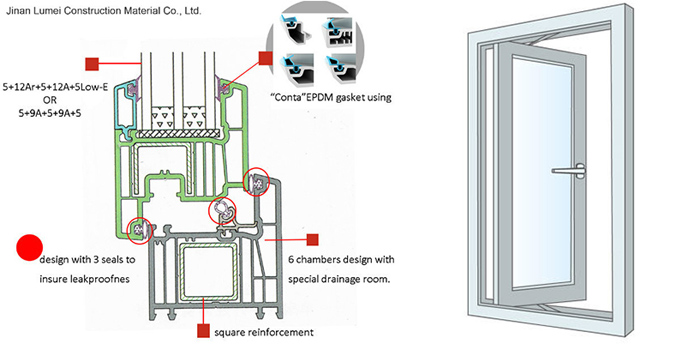

Due to the use of plastic steel profiles with low thermal conductivity, uPVC Window has significant cost advantages when achieving high practical effects of environmental protection and energy saving. In Northeast China and other places, the weather is very cold in order to better environmental protection and energy saving effect, the proportion of plastic steel windows is very large, and the market share of plastic steel windows is high. The window is equipped with more than 70 inner cavity aluminum profiles, with three glass and two hollow LOWE laminated glass, and three sealing system software. The thermal conductivity of the whole window is very easy to guarantee 1.5W/m²·K, even if it is guaranteed to be in a passive window of 0.8W/ The m²·K value is also relatively easy. Because plastic steel windows can achieve high environmental protection and energy saving at relatively low cost, plastic steel windows still occupy a certain sales market.

The production of uPVC Profile has gone through the whole process of seasoning, wrong material, extrusion, refrigeration setting, traction belt laser cutting, inspection, packaging and so on. Plastic steel profile is a kind of hard polyethylene polymer material plastic that is the first to undergo the entire seasoning process. After the R&D department has clarified the secret recipe, this work is carried out by the seasoning process. The seasoning process has an automated production line, which is also carried out by manpower. The composition of the secret recipe is composed of more than ten kinds of raw materials such as PVC, halogen-free flame retardants, fillers, lubricating fluids, processing aids, light stabilizers, and color pastes. There are special regulations for each raw material and cannot be abused.

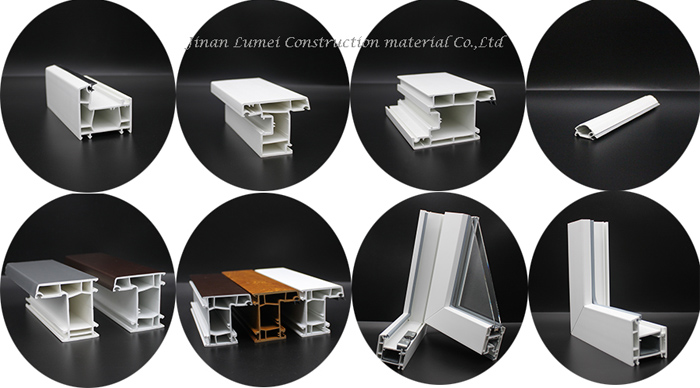

Related Products

Submitted successfully

We will contact you as soon as possible